Advances in Animal and Veterinary Sciences

Research Article

Using the Histological Method to Identify the Turkey Meat Thermal State

Diana Orlova*, Alexander Drozd

St. Petersburg State University of Veterinary Medicine, 5, Chernihiv Str., St. Petersburg, Russia.

Abstract | Meat quality control allows revealing meat obtained from sick poultry, species substitution, and falsification of chilled raw materials with cheap defrosted meat. The thermal state of fresh flesh and repeatedly defrosted meat determining by organoleptic indicators and histological methods. However, organoleptic methods are entirely subjective. Histological examination in the production environment is difficult and time-consuming. As an alternative to the histological to examine meat, it has been developed the express method. In this method, the sample placed between glasses of compressorium in form of thin section and stained by hematoxylin-eosin. All of the data has been processed by STATISTICA 13.3. Using hematoxylin-eosin on chilled meat allows detections of the striated muscle tissue. The cytoplasm turns pink. The nuclei of muscle fibers become purple. Muscle fibers are densely, unidirectionally concerning each other, the structure of the tissue preserved. Defrosted meat has a disturbed structure of the muscle tissue. Besides, there found the thickenings at the ends of the muscle fibers. Such formations explained by the weakening of the sarcoplasm as a result of freezing and subsequent thawing. Applied compression in the express method promotes the exit of sarcoplasm beyond the boundaries of muscle cells and facilitates its identification. A clear identification sign that allows us to differentiate the thermal state of raw meat in native preparations is the presence of thickenings at the ends of muscle fibers, which are absent in preparations of chilled material. The proposed method will simplify the meat control system and ensure food security.

Keywords | Defrosted meat, Meet quality, Quality control, Express method, Hematoxylin-eosin

Received | July 06, 2020; Accepted | August 28, 2020; Published | September 20, 2020

*Correspondence | Diana Orlova, St. Petersburg State University of Veterinary Medicine, 5, Chernihiv Str., St. Petersburg, Russia; Email: diorlova@rambler.ru

Citation | Orlova D, Drozd A (2020). Using the histological method to identify the turkey meat thermal state. Adv. Anim. Vet. Sci. 8(s2): 12-17.

DOI | http://dx.doi.org/10.17582/journal.aavs/2020/8.s2.12.17

ISSN (Online) | 2307-8316; ISSN (Print) | 2309-3331

Copyright © 2020 Orlova and Drozd. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

INTRODUCTION

Currently, turkey meat production is an essential sector of the meat industry in Russia. These products are of particular interest among consumers who want to join the principles of a healthy lifestyle and diversify the diet with a new dish. Besides, turkey meat deservedly occupies a leading position in dietary, medical and preventive, as well as baby food. Because turkey meat characterized by high nutritional and biological value. However, turkey meat obtained from sick poultry, produced and handled with non-compliance with veterinary and sanitary requirements, can pose a threat to human health. Such meat can be a source of pathogenic and opportunistic microorganisms, toxic and toxic substances. Turkey meat has a rather high cost in the Russian market, which for unscrupulous suppliers can serve as a reason for the release of poor-quality, unsafe or falsified products (Orlova et al., 2019).

Ensuring the quality and safety of food products is an integral part of maintaining the health of the population and maintaining a high level of economic development of the country. Following the Doctrine of Food Security of the Russian Federation, approved by Decree of the President of the Russian Federation of January 21, 2020, N 20, food security is an essential component of the demographic policy. It is a prerequisite for improving the quality of life of citizens through the implementation and implementation of practical solutions that meet the requirements of international standards.

One of the main objectives of food security is to ensure food safety. It achieved by controlling agricultural products and food at all stages of production, storage, transportation, processing, and marketing. Implement such control. The current Russian legislation provides for several methods and techniques. It was using these rules, establishing the benignity of food products, identification characteristics, and the safety of its use at all stages of circulation.

As part of the monitoring by the regulatory authorities in the production, identified cases of using turkey obtained from sick poultry, stale products, species substitution, and falsification the chilled raw meat with cheap defrosted meat. Turkey meat is gaining popularity among consumers and has excellent taste and consumer qualities. Turkey meat contains a large number of complete proteins, vitamins, minerals, and a small amount of fat. This meat occupies a high price sector of citizens’ consumer basket (Orlova et al., 2019).

The chemical composition and nutritional value of turkey meat depend on its thermal state. When processing it at subzero temperatures, the free water contained in muscle cells crystallizes, and crystals formed mechanically damage the sarcolemma. When meat defrosted, destroyed muscle fibers lose the cytoplasm and nutrients (Khvylya et al., 2019).

Currently, methods to determine the thermal state of raw meat and identifying repeatedly defrosted meat based on organoleptic indicators and histological examing of muscle tissue structure and muscle fibers integrity. However, organoleptic methods are entirely subjective. The histological examination into the production environment is difficult and requires specialized training of personnel and laboratory equipment. The histological examination takes a long time, which loses its relevance in conditions in the real circulation of meat products (Khvylya, 2016).

To ensure the release of the right chilled products and the exclusion of substitution chilled turkey meat by defrosted, need a quick, effective, and secure method.

MATERIALS AND METHODS

For the study, used parts of turkey carcasses (wing, thigh, drumstick, chest) in a total amount were 37 samples. At first, sampling carried out according to normative technical documentation. The samples were placed in refrigeration and freezers to maintain different temperatures to freeze and cool the material. Cooling parameters were 0 to 2 °C, and relative humidity 80-85%. Freezing parameters were -12 °C by the relative humidity of 80-85%. Subsequently, chilled products stored for three days and frozen products for ten days.

Then has been carried out the organoleptic analysis and studying the microstructures the tissues of chilled and defrosted meats by histological examing and native preparations.

The samples were thawed at room temperature until the ice crust disappeared from the surface and inside the examples. The presence of ice inside the test material was determined not through the cut of the knife, part of the turkey meat after defrosting was re-sent to the freezer.

Given the primary goal of the studies to justify the possibility of using the microscopy method of native turkey meat preparations to identify the thermal state, we first evaluated the organoleptic characteristics and morphological characteristics of the muscle tissue of the chilled products, which taken as control ones. We then compared them with the corresponding features of the muscle tissue of similar defrosted products.

Organoleptic studies of turkey meat performed according to GOST 31470-2012 “Poultry meat, offal, and semi-finished products from poultry meat. Methods of organoleptic and physicochemical research. “ In organoleptic studies of meat, the appearance, color, condition of the muscles on the surface and section, consistency, smell, transparency, and aroma of the broth vapor were evaluated using a boiling test.

Appearance and color were determined by visual inspection, immediately after cutting the muscles in the deep layers. At the same time, attention drawn to the presence of stickiness of the meat from the surface and its moisture content in the cut by applying filter paper to the cut surface and evaluating the wet traces remaining on it. The meat consistency determined by pressing on its surface with a spatula and observing the rate of leveling of the resulting fossa. The smell evaluated from the surface, and in deeper layers during the cut, particular attention paid to the scent of meat adjacent to the bone. Besides, the color, aroma, and consistency of fat established by squeezing and rubbing it between the fingers.

For sampling by cooking, the meat ground with scissors to the state of mincemeat. At the same time, the connective and fatty tissue separated, and 20 g sample taken, placed in a 100 cm3 conical flask, 60 cm3 of distilled water added, the container covered with a watch glass, put in a water bath and heated to a temperature of 80-85 °C. When the first vapors of the broth appeared, evaluated its smell, noted the presence of extraneous odors, an acidic or putrid odor. The transparency of the soup, the presence of flakes in it, was evaluated in transmitted light, pouring the brew into a measuring cylinder.

Histological examination of meat carried out by GOST 19496-2013 “Meat and meat products. Method of histological examination”, which allowed to obtain high-quality histological preparations.

Microscopy of histological preparations assessed the breakdown of muscle fibers, the presence of voids inside the muscle cells. Between them, thickened myofibrils examined 20 fields of view at a magnification of x100, each of the above criteria calculated in each area of view. Then estimated the arithmetic mean for each sample of chilled and defrosted products.

As an alternative method to the classical histological method for the study of meat, proposed an express method for studying the microstructure of muscle fibers in native preparations. Crushed slices meat put in between the thin glass of the compressorium and stained with hematoxylin-eosin, which made it possible to evaluate the structure of turkey muscle tissue. This method is available in performance and does not require special equipment and specialist qualifications (Kalyuzhnaya et al., 2019).

A sample weighing 20 grams was taken from an example of raw meat, fixing it with tweezers. Curved scissors, directing their blades with the convex side out, make five thin sections along the muscle fibers 1 cm long and 2 mm thick. Next, they laid out using dissecting needles on the bottom glass of the compressorium with intervals of at least 1 cm between them. Carefully cover the sections with the upper lens, taking it away from the lower glass as much as possible, press the glasses with each other with force, and shift them in the opposite direction, keeping compression to the starting position. The lenses are fixed with screws, thereby giving the muscle slices the thin necessary configuration available to view the muscle structure in the light beam of the microscope.

Then the screws are unscrewed, the crushed sections carefully removed with dissecting needles and placed on the bottom of the porcelain cup, after which they stained with hematoxylin-eosin. First, 3-4 drops of Ehrlich alum hematoxylin are added to the porcelain cup with slices and stained for 3-4 minutes. Next, the sections are washed in water for 2 minutes until the cleaned water discolored. For complete removal of hematoxylin, the parts are dipped in a 1% hydrochloric acid solution until a slightly pink color appears. They are placed in a 1% ammonia solution until the liquid stains blue and washed with water within 2 minutes. Then the muscle sections are treated with a 1% aqueous-alcoholic solution of eosin for 1 min and washed again with water (Shchebentovska et al., 2015).

After that, the colored sections with the help of dissecting needles, while leveling, are placed one at a time on the lower glass of the compressorium, one drop of 50% aqueous glycerol solution added to the sections and the muscle tissue fixed, pressing it slightly with the upper glass and tightening with screws. Thus, prepared micro preparation is available for microscopy and structural evaluation of the elements of muscle fibers.

Microscopy was performed under a light microscope to increase the lens ten and eyepiece ten while assessing the structure of muscle tissue, the number of breaks in muscle fibers, the shape, and condition of their ends, looking at 20 fields of view, each of the above indicators calculated, and then the arithmetic average for each sample was computed turkey meat for the entire example of 37 samples.

The obtained results of the studies were processed using Microsoft Office Excel application programs and Statistica 10, as well as by the method of variation statistics with the calculation of arithmetic mean values of the correlation coefficient: M is the arithmetic mean, m is the arithmetic say error, the significance of differences between the samples was determined by the Student t-test in Microsoft Office Excel (p <0.001).

RESULTS AND DISCUSSION

An organoleptic analysis of defrosted turkey meat stored at temperatures up to -12 °C by general indicators corresponded to lower quality products than chilled raw materials. At the external examination, there was no drying crust. The meat surface was moist when the meat was pressed on the flesh, the pit slowly straightened (turkey breast), a wet trace remained on the surface of the fingers, which confirms the release of a small amount of meat juice. The color of the meat is slightly pink on the surface in the section is weak pink. Odor on the surface and in the cut of the product is somewhat trapped. The aroma of the broth not pronounced can see the dark brew with not a lot of flakes. Fat defrosted meat raw materials, slightly yellowish, there is an unexpressed specific odor, soft consistency.

Re-frozen raw materials were stored in the freezer at -12 °C for another three days, after which we thawed them at room temperature and conducted organoleptic studies. The appearance of the product was with a relatively abundant amount of moisture, light pink, the smell was weak, the color in the section was slightly pink, the scent was almost not pronounced, the stratification of muscle fibers visualized. When pressing on the turkey meat with fingers, a small amount of meat juice expired, the skin surface became sticky, with a specific unpleasant odor. During the preparation of the cooking sample, the smell of the broth poorly perceived. The color of the soup was gray - yellow, cloudy with a large number of flakes, and a flocculent precipitate. Examining the fat of re-frozen products, one can say about its unsatisfactory organoleptic evaluation. He had a yellow color. When rubbing a piece of fat between the fingers, the specific smell was slightly perceived, the consistency corresponded to a limp one (Tokarev et al., 2019).

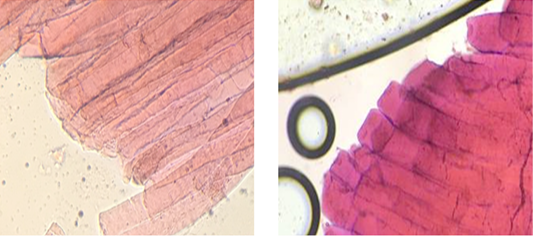

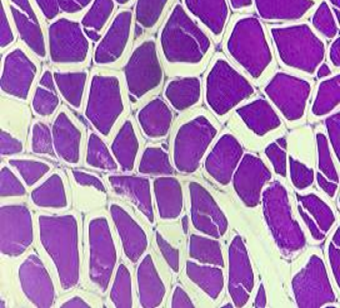

A histological examination of the cross-section of the chilled and defrosted product revealed several differences in the muscle tissue of the bird. Microscopy of preparations of chilled meat raw materials visualized an even tissue structure, an integral state of muscle fibers, the distance between them, as well as between the muscles themselves, was secured into a visible pattern, without gaps and violation of the interval in the intervals concerning similar structures (Figure 1).

Figure 1: Histogram of chilled turkey meat.

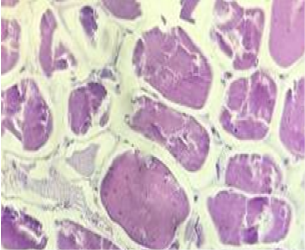

Figure 2: Histogram of defrosted turkey meat.

Examining histological samples of cross-sections of defrosted turkey meat using light microscopy, significant changes observed in the structural arrangement of elements of muscle tissue.

So, in defrosted turkey meat, muscle cells were visualized chaotically, there was no clear tissue structure, cell breaks were detected, as a result of which they acquired an irregular shape with the formation of voids inside the fibers, found thickened fibers (Figure 2). In contrast, in similar preparations made from chilled products, similar morphological changes observed in isolated cases or not found in the material (Khvylya et al., 2012).

Analyzing obtained values (Table 1), found that the number of thickenings of myofibrils in defrosted products was 5.74, which is 2.66 times more than in chilled products. Some voids inside the muscle fibers and between them are 2.56 times more than in refrigerated raw materials; the number of breaks in muscle fibers of defrosted meat was 42.07, which exceeds this value in refrigerated products by 15.7 times. The obtained values are statistically significant - p <0.0001.

Table 1: Morphological characteristics of muscle tissue in histological preparations of chilled and defrosted samples of turkey meat (M±m. n = 37).

| Characteristic | Chilled products (control) | Defrosted products |

| The number of breaks in muscle fibers. units / 20 insight | 2.67±0.22 | 42.07±1.02* |

| The number of voids inside the muscle fibers and between them. units / 20 insight | 1.02±0.11 | 2.63±0.12* |

| Thickening of myofibrils. units / 20 insight | 2.16±0.12 | 5.74±0.18* |

* p <0.0001 – a statistically significant difference from control.

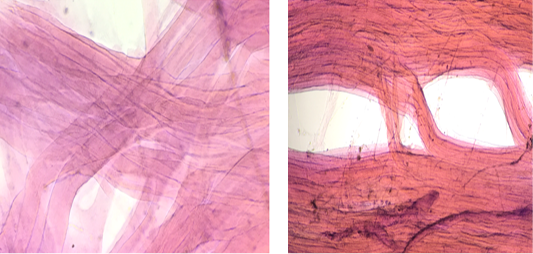

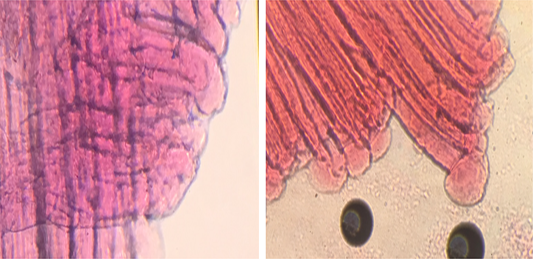

In native preparations of chilled poultry meat stained with hematoxylin-eosin, striated muscle tissue is visible. The cytoplasm colored in pink, the nuclei of muscle fibers, painted in purple, are also visible. Muscle fibers are tight, unidirectional to each other, the structure of the tissue preserved. The ends of muscle fibers are smooth, steep (Figure 3).

In native preparations of defrosted meat, found a violation of the structure of muscle tissue, the fibers were randomly located, with breaks and a breach of a single direction. Besides, thickenings found at the ends of the muscle fibers. Such formations explained by weakening of sarcoplasm as a result of freezing and subsequent thawing, its exit beyond the limits of muscle cells, which facilitated by squeezing in manufacture sections.

In the study of native preparations from defrosted poultry meat, we found that muscle fibers have the form of “torn”. The ends of muscle fibers are swollen, rounded at both ends (Figures 4 and 5).

Table 2: Assessment results of native preparations of chilled and defrosted turkey meat samples (M±m. n = 37).

| Characteristic | Chilled products (control) | Defrosted products |

| The number of breaks in muscle fibers. units / 20 insight |

0.48±0.09 |

4.81±0.27* |

| The number of voids inside the muscle fibers and between them. units / 20 insight |

0.29±0.08 |

11.46±0.58* |

| Thickening of myofibrils. units / 20 insight | - | 20.33±0.41 |

* p <0.0001 – a statistically significant difference from control.

When analyzing the results of microscopy of native meat preparations (Table 2), it found that the number of fibrous sections of muscle tissue in defrosted products is 10.01 times greater than in samples of chilled; muscle fiber breaks - 39.5 times. A striking identification sign that allows us to differentiate the thermal state of raw meat in native preparations is the presence of thickenings at the ends of muscle fibers, which are absent in preparations of chilled material. The obtained values are statistically significant - p <0.0001.

CONCLUSIONS AND RECOMMENDATIONS

The identification of the thermal state of meat in modern conditions of the food industry and economic activity is crucial in ensuring food security and protecting the interests of consumers. Histological examination is the most informative, reliably allows differentiating chilled meat products at any stage of its circulation. The obtained research results will enable us to use the proposed method of manufacturing and microscopy of native meat preparations and establish the previous freezing of products. The identification criteria, in this case, are a violation of the structure of muscle tissue, which is manifested by the presence of fibrous areas, ruptures of muscle fibers, as well as the presence of thickenings at the ends of muscle fibers (Kalyuzhnaya et al., 2019).

The use of this method is acceptable and promising for the implementation of input and production control of raw meat, which will generally improve the quality and safety of food products sold.

This method is easily and quickly reproducible, does not require expensive equipment and special skills, and can be universally applicable to identify defrosted meat of farm animals and to prevent falsified chilled products from being sold, including during the incoming control of raw meat in places of storage and sale.

The proposed method will allow identification of chilled and frozen products during an incoming inspection of meat raw materials at processing plants and in laboratories for the veterinary and sanitary examination of food markets and in places where products sold. This approach can simplify the meat circulation control system, ensuring food safety by the current legislation.

AUTHOR’S CONTRIBUTION

Diana Orlova is scintific leader and developer of this research and Alexander Drozd was conducting meat histological examination and prepared its results as a scientific article.

CONFLICT OF INTEREST

The authors have declared no conflict of interest.

REFERENCES