Advances in Animal and Veterinary Sciences

Research Article

Typology of the Cameroon Traditional Slaughterhouses Based on Hygiene Practices

Raoul Bakari Afnabi1*, Rodrigue Poueme Nameni2, Sylvain Sado Kamdem3, Victor Ngu Ngwa1, Jean Justin Essia Ngang3

1University of Ngaoundere, School of Veterinary Medicine and Sciences, Department of Microbiology and Infectious Disease, P.O. box 454 Ngaoundere, Cameroon. 2 National Veterinary Laboratory (LANAVET), Service of Epidmiology, P.O box 503, Garoua, Cameroon. 3University of Yaounde I, Faculty of Sciences, Department of Microbiology, P.O. box 812 Yaounde, Cameroon.

Abstract | In order to characterise traditional slaughterhouses, an inquiry was carried out in Northern Cameroon. A questionnaire was administered to 469 assistant butchers chosen from 15 traditional slaughterhouses in the zone. The inquiry enabled us to evaluate the perception of basic rules of hygiene by these assistant butchers in the chosen slaughtering sites. A chart enabled us to list out all the hygiene practices in relation to the guide to good hygiene practice and the application of the HACCP (Hazard Analysis Critical Control Point) principles in the slaughtering and cutting activities (GGHPAHPSCA). Multivariate analysis was applied on the data collected from the questionnaires and the inventory charts. Accordingly, the understanding of basic hygiene rules among employees of the selected slaughterhouses was identified as fairly good (67%), average (26%) and poor (5%). The best conception of hygiene practices was attributed to those employees with at least a primary education and the bad practices to those who were illiterate. The performance of good hygiene practices was fairly well observed at the Garoua council slaughterhouse, while the average and bad practices of hygiene were linked to traditional slaughterhouses having a partial and bad cleaning implementation, respectively. Whatever the types of traditional slaughterhouses, the hygiene practices common to slaughterhouses of Northern Cameroon were essentially linked to the poor management of personnel and the treatment process of carcasses during production.

Editor | Kuldeep Dhama, Indian Veterinary Research Institute, Uttar Pradesh, India

Received | July, 11 2014; Revised | September 22, 2014; Accepted | September 24, 2014; Published | October 03, 2014

*Correspondence | Raoul Bakari Afnabi, University of Ngaoundere, Cameroon.; Email: bakariafnabiraoul@yahoo.fr

Citation | Afnabi RB, NameniRP, Kamdem SS, Ngwa VN, Ngang JJE (2014). Typology of the Cameroon traditional slaughterhouses based on hygiene practices. Adv. Anim. Vet. Sci. 2 (8): 477-487.

DOI | http://dx.doi.org/10.14737/journal.aavs/2014/2.8.477.487

ISSN (Online) | 2307-8316; ISSN (Print) | 2309-3331

Copyright © 2014 Afnabi et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

INTRODUCTION

In developing countries like Cameroon, the production of quality meat remains a crucial problem (Trent et al., 2003). Slaughterhouses put forward as excellent production sites for beef are in most of the cases slaughter slabs (traditional slaughterhouses). It is only in the towns of Yaounde and Douala that old modern slaughterhouses can be found (Mravili et al., 2013). This traditional system of beef production is generally marked by the treatment of animals (ante and post mortem) without any considerations of good hygiene practices (Heinz, 2008). This constitutes a serious public health problem today because many studies have identified the presence of dangerous germs of public health importance in these traditional slaughterhouses (Seeiso and McCrindle, 2009; Swai and Schoonman, 2012). Actually, many studies related on the description of hygiene practices observed in these traditional slaughterhouses have been carried out in Africa. Indeed, Adeyemo et al. (2009) presented the cruel handling of cattle at the Akinyele cattle market and slaughter slab in Oyo State, (Nigeria) while Komba et al. (2012) and Ndalama et al. (2013) portrayed the sanitary practices in cattle at slaughterhouses in Tanzania as poor. However, to our knowledge, no research has been carried out in Africa in general and Cameroon in particular, on the characterization of traditional slaughterhouses, especially on the application of good hygiene practices in modern slaughterhouses. Therefore, this study was undertaken to classify traditional slaughtering sites based on sanitary practices in the northern regions of Cameroon. In addition, knowledge, practices and perception of basic hygiene rules of assistant butchers in traditional slaughtering sites were accessed.

MATERIALS AND METHODS

Data Collection

To characterize the traditional systems of beef production in Northern Cameroon, inquiries were carried out between April and October 2013. Fifteen slaughterhouses were targeted in the three northern regions of Cameroon and used for this study (Table 1). Two surveys were performed. The initial research carried essentially on the evaluation of the perception of assistant butchers (main actors implicated in the process of beef production in the slaughterhouses) of basic hygiene rules. A structured questionnaire was administrated to assistant butchers in order to collect information on their education level, their age and their knowledge of the cleaning of their uniforms and utensils.

The second research enabled us to make an inventory of the sanitary practices used at the targeted slaughterhouses. Hygiene practices were accessed using an inventory chart developed based on guide of Good Hygiene Practice and the Application of Principles of HACCP (Hazard Analysis Critical Control Point) in the Activities of Slaughtering and Cutting (GHPAPHASC) (Michel et al., 2010).This chart was filled by veterinary sanitary inspectors in the slaughterhouses chosen. This GGHPAHPSCA was conceived by the French associations of meat professionals, according to the methods recognized by the Codex Alimentarius and ideas brought by the NF EN ISO 22000 (2005) standard.

The questionnaire was translated into Fulfulde, tested and administered by a team of investigators (one to two persons per town) capable of expressing themselves perfectly in French and Fulfulde. These persons were recruited and trained in each town where the traditional slaughterhouses were to be studied. The second investigation was carried out by one person who was equally trained for that purpose. The methodology chosen for the selection of the assistant butchers to be questioned was by the census method (Giannelloni and Vernette, 2001). In all, and for the study on the perception of hygiene of the assistant butchers, 469 workers in the slaughterhouses were selected in the fifteen chosen slaughterhouses (Table 1).

Statistical Analysis

The questionnaires collected from the inquiry were compiled and treated by the Sphinx plus2 4.0 software. A Multiple Factorial Correspondence Analysis (MFCA) was used to evaluate perception of hygiene by assistant butchers. To this effect, 8 active variables (the basic hygiene rules considered) and 3 supplementary variables in the identification of assistant butchers were taken into account. In the research on the nature of the beef production system, 64 active variables (hygiene practices observed) associated with 29 supplementary variables were considered for MFCA. The status of individuals representing the samples considered was defined using Hierarchical Ascendant Classification (HAC).

Neural Discriminant Analysis (NDA) was used to confirm the HAC results. The models from which these NDA were carried out are presented below:

For the research on the perception of basic hygiene rules:

V12 = V1+ V2+ V3 +V4+ V5 +V6 +V7+ V8

With:

V12 ↔ quality of the perception of basic hygiene rules (dependent variables);

V1 to V8 ↔ to the basic hygiene rules considered (explanatory variables).

On the research on the nature of the production sys tem:

V94= V1+ V2+……………………………. +V64

With:

V94 ↔ Type of slaughterhouse (dependent variable);

V1 to V64 ↔ in the hygiene practices observed (explanatory variable).

The multi- dimensional analysis and the neural discriminant analysis were done by the SPAD 5.0 software.

Table 1: Regions and slaughterhouses studied.

|

Regions |

Cities |

Traditional Slaughterhouses (sl) |

Assistant Butchers surveyed |

Average of beefslaughtered per day |

|

Far-North |

Maroua |

Maroua Municipal sl Makabai Municipal sl Kongola Djideo Municipal Kongola Djolao Municipal sl |

38 21 10 10 |

30 10 7 6 |

|

Kousseri |

Kousseri Municipal |

36 |

15 |

|

|

Yagoua |

Yagoua Municipal sl |

14 |

3 |

|

|

North |

Garoua |

Garoua Municipal sl Pitoa-Garoua Municipal sl Pitoa Municipal sl |

100 30 18 |

25-30 25 3 |

|

Guider |

Guider Municipal sl |

22 |

10 |

|

|

Adamaoua |

Ngaoundere |

Ngaoundere Municipal sl Manwi Municipal sl Dang Municipal sl |

96 16 33 |

45-50 4 6 |

|

Meiganga |

Meiganga Municipal sl |

16 |

10 |

|

|

Tibati |

Tibati Municipal sl |

8 |

4 |

RESULTS

Perception of Hygiene by Assistant Butchers

Multiple Factorial Correspondence Analysis (MFCA)

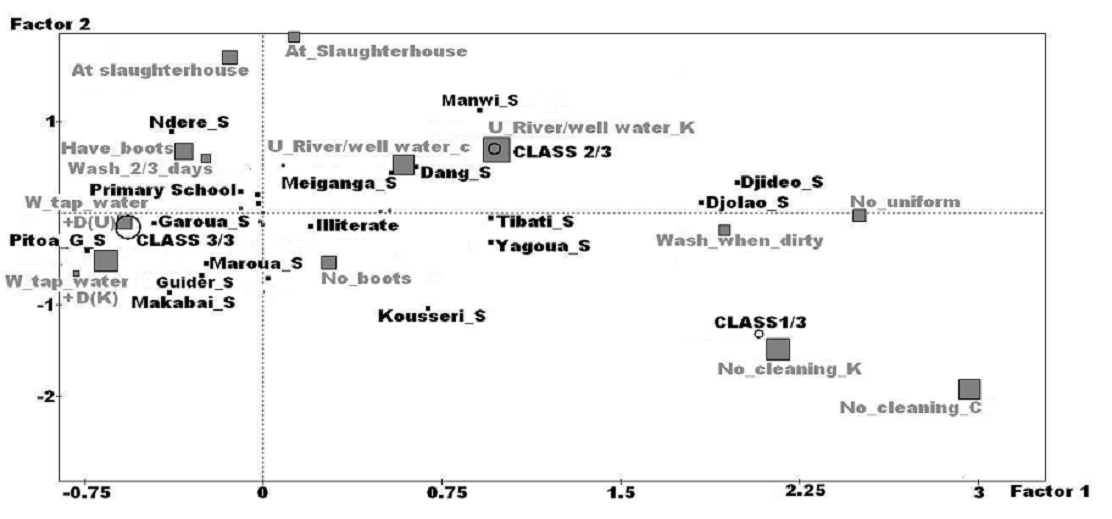

The MFCA shows that axes 1, 2, and 3 will describe 33% of existing associations between the variables studied. Axis 1 opposes the modality related to the cleaning of working utensils using tap water and detergents to that represented by the absence of cleaning of working utensils. This antagonism is illustrated by a 38% contribution (ctbr) in the forming of axis 1 (contribution to the overall variance: 12.41%), of the variable corresponding to these modalities. Otherwise, the respective cos (0.379 and 0.442) of the modalities such as the washing of clothes and working utensils using tap water and detergent, reveal a strong connection between the variables representative of these modalities (Figure 1). This axis also reveals the association between the group of modalities concerning the absence of cleaning utensils ((test value) vt: 10.6), the washing of work clothes with river/well water (vt: 12.6), to the illiteracy modality (vt: 3.4).

1- At slaughterhouse: Keep working knives at slaughterhou; 2- At_Slaughterhouse: Keep working clothes at slaughterhouse; 3-Ndere: Ngaoundere; 4- No_cleaning_C: No cleaning of working clothes; 5- No_cleaning_K: No cleaning of working knives; 6-Pitoa_G: Pitoa-Garoua; 7-S: Slaughterhouse; 8- U_River/well water_c: Use of river or well water to wash working clothes; 9- U_River/well water_K: Use of river or well water to wash working knives; 10- W_tap_water (K): Wash the knives of work with tap water; 11- W_tap_water+D (K): Wash the knives of work with tap water and detergent; 12- W_tap_water+D (U): Wash the uniform of work with tap water and detergent; 13- Wash_2/3_days: Wash work clothes every two to three days;  Modality of active variable;

Modality of active variable; Modality of illustrative variable;

Modality of illustrative variable; Perception class of basic hygiene rule of assistant butchers.

Perception class of basic hygiene rule of assistant butchers.

These habits were observed at the slaughterhouses of Kongola (K) Djideo (vt: 6.3); K. Djolao (vt: 5.1) and Kousseri (vt: 4.3). Whereas the slaughterhouses of Garoua (vt: 5.1); Pitoa-Garoua (vt: 4.2) and Ngaoundere (vt: 4.2), were found most of the assistant butchers with a primary school education (value test: -3.05) and who wash their clothes and work utensils with tap water and detergent.

Axis 2 (contribution to the overall variance: 10.64%), confronts the first series of selected modalities by the absence of gumboots (ctrb: 10.25%) and the washing of work clothes with tap water and detergent (ctrb: 8%), to the second series of modalities comprising the pair of boots possession (ctrb: 12.54%) and the washing of work clothes in river/well water (ctrb: 8.7%). The first series was illustrated by those assistant butchers having less than 30 years of age (vt: -5.08) and working in the slaughterhouses of Kousseri (vt: 6.5); Maroua (vt: 3.5); Makabai (vt: 3.9); Guider (vt: 3.2) and Pitoa (vt: 3.1). While the second series presented assistant butchers that were more than 30 years of age (vt: 3.38) and working in the slaughterhouses of Manwi (vt: 4.6) and Ngaoundere (vt: 9.8).

No matter the age and/or the education level, axis 3 (contribution to the overall variance: 10.31%) opposes the absence of work utensils cleaning (ctrb: 6.26%) to the daily washing of these utensils (ctrb: 1%). On top of this, the absence of frequency in the work utensils cleaning (ctrb: 25%) and the washing of utensils with river/well water (ctrb: 8.5%) were opposed to this axis. The assistant butchers of the Kousseri (vt: 3.2) and Ngaoundere (vt: 5.3) slaughterhouses revealed the lack of utensils cleaning, while those of the Dang (vt: 2.2) and K. Djideo (vt: 5.9) slaughterhouses wash their utensils in river/well water. All the modalities, which make up axes 1 and 2 are represented proportionally to their contribution to the axes in figure 1.

The multiple factorial correspondence analysis formerly carried out showed the tendencies in the perception of elementary hygiene rules observed in the traditional system of beef production in Northern Cameroon. The confirmation of these tendencies passes through the consideration of the types of individuals considered.

Hierarchical Ascendant Classification (HAC)

The hierarchical ascendant classification carried out on the individual considered, enabled us to distinguish three categories of individuals (Figure 1). The first class identified (1/3), was characterized by the modalities such as the absence of washing utensils (vt: 12.2); the non-existant frequency in the utensils cleaning (vt: 8); the lack of boots (vt: 3.79) and illiteracy (vt: 2.37). As such, 28% of assistant butchers from the Kousseri municipal slaughterhouse belonged to this class.

Class 2/3 contained those workers (124) who distinguished themselves by their aptitudes in cleaning their utensils (vt: 20.97) and their work clothes (vt: 12.9) with river/or well water. The slaughterhouses to which these assistant butchers belonged to were mainly those of Dang (69.7%); Manwi (87.5%); K. Djideo (100%); K. Djilao (100%); Meiganga (56.25%); Yagoua (50%) and Tibati (50%).

The modalities concerning the cleaning of utensils (vt: 17.81) and clothes (vt: 13.01) with tap water and detergent, constituted Class 3/3. It united assistant butchers (317) who have gone through primary school (vt: 3.52). The slaughterhouses concerned in this category are those of Ngaoundere (90.53%); Garoua (80%); Pitoa-Garoua (90%); Makabai (94.74%); Maroua (79%); Guider (86%) and Pitoa (72%).

In order to confirm the results from the classification done, a neural discriminant analysis (NDA) was carried out.

Neural Discriminant Analysis (NDA)

The analysis reveals the variability in the learning cost of 2* 10-2 to 0.002* 10-2 that is a decrease in gap of the measures calculated between the real classes and the classes provided by the sample during the learning process. The results of this analysis present three distinct classes of individuals (Table 2) corresponding to the classes found in the HAC.

The Characterization of Beef Production Systems

MFCA

To undertake the MFCA, the variable classifying the perception of elementary hygiene rules was created and associated to other variables describing the hygiene practices observed at the level of traditional slaughterhouses.

The examination of hygiene practices observed in the traditional slaughterhouses revealed two main axes which will describe 40% of associations between the variables determining the production systems.

Axis 1 (contribution to the overall variance: 27.94%) presented two series of modalities opposing each other. The first series comprised the absence of meat contamination by by-products; the compliance with norms of storage sites of waste and their recognized by- products; the effective presence of chemical products storage facilities and the cleaning of saws/axes. The second series came back on those modalities, which are contrary to the first. These two series described the behaviour of the four variables, which contributed each to 7% in the forming of the factorial axis. The illustrative modality, Garoua municipal slaughterhouse (vt: -3.6) equally reveals a good association to the modalities described in the first series.

The contribution of axis 2 to the global variation is 11.9%. This variability was perceived through a solid liaison especially those modalities such as non-compliant surfaces; non-compliant buildings; the cleaning of the means used in the transportation of the meat and the weak mobilization by the entire management of all the personnel on food safety.

Parallel to this, a strong proximity will be described between the modalities like the absence of mobilization of the management of the entire staff on food safety; the non-compliance of the building and the surfaces; the lack of cleaning and disinfection of means of transportation of the meat. The variables put forth by these modalities all had contributions, which varied between 7.3% and 11.8%. However, the Dang municipal slaughterhouse with a test value of 2.34 stands out as the site where the first modalities were observed. The entire modalities making axes 1 and 2 are proportionally represented to their contribution on the different axes in figure 2.

Table 2: Classification percentage of the slaughterhouses worker hygiene perception.

|

Output classes |

Assistant butchers hygiene perception |

Higlyranked |

Badlyranked |

Total |

% of highlyranked |

Purety of ranking |

|

Class 1/3 |

Bad hygiene perception |

28 |

0 |

28 |

100 |

100 |

|

Class 2/3 |

Average hygiene perception |

124 |

0 |

124 |

100 |

100 |

|

Class 3/3 |

Fairly good hygiene perception |

317 |

0 |

317 |

100 |

100 |

|

Total |

469 |

0 |

469 |

100 |

100 |

1- C _meat/byproducts: Contamination of meat by by-products; 2- CWS: Comply with standards; 3-Dji: Djideo; 4- DRFS: Decision related to food safety; 5- E: equipments; 6- G: Good; 7-Gdr: Guider; 8-Kssr: kousseri; 9- MT: Management team; 10-Mgg: Meiganga; 11-Ndere: Ngaoundere; 12- PCWS: Poor compliance with standards; 13-Pitoa_G: Pitoa-Garoua; 14- S_downstream_winds: Slaughterhouse situated downstream of prevailing winds; 15- Surf : Surfaces; 16-Tbi: Tibati; ⃝ Class 1/3;  Slaughterhouse belonging to class 1/3; ∆ Class 2/3; ◊Slaughterhouse belonging to class 2/3;

Slaughterhouse belonging to class 1/3; ∆ Class 2/3; ◊Slaughterhouse belonging to class 2/3;  Class 3/3;

Class 3/3;  Slaughterhouse belonging to class 3/3; □Hygiene practices observed at slaughterhouses

Slaughterhouse belonging to class 3/3; □Hygiene practices observed at slaughterhouses

Hierarchical Ascendant Classification (HAC)

The HAC carried out enabled us to put together the fifteen traditional meat production systems studied in relation to the similar hygiene practices noticed. After the analysis, three different classes stood out, notably 1/2, 2/3, and 3/3 (Figure 2). The first, class 1/3 is different from the others in the cleaning of production materials and the surfaces used, which comply only in part with the norms (vt: 2.54). The slaughterhouses of Maroua, Pitoa-Garoua, Yagoua, Dang, Ngaoundere and Guider correspond to the production sites belonging to this class.

The second class (2/3), revealed contrary to the oth-ers, as particularities the cleaning of its surfaces and production materials not in compliance to the norms(vt: 3.02), the surface area of the building not in compliance (vt: 2.46) and a lay out plan not in compliance (vt: 2.37). The structures, which, fall in this class were slaughterhouses of Meiganga, Tibati, Manwi, Kousseri, Pitoa, K. Djoloa, K.Djideo and Makabai. Class 3/3 was only represented by the Garoua municipal slaughterhouse. Whatever the classes identified, the HAC showed (Table 3) the list of common characteristics to these traditional slaughterhouses in Northern Cameroon. Therefore, the management of the personnel/the work force (the organization of medical follow up; the training and cleanliness of the personnel) contributed to 28% in the setting up of common sanitary practices. Whereas, the follow up of the production process (the method of work during production; the treatment of by-products; cleaning and disinfection), have contributed to 56% in the constitution of hygiene practices found in all the traditional slaughterhouses studied.

Table 3: Common hygienic practices in the traditional slaughterhouses.

|

The common characteristics to all the studied traditional slaughterhouses |

|

The Stunning, bleeding, dressing, evisceration and others, are quickly carried out (R146) |

|

The non-existence of workshop is nearly complete (the slaughter hall; tripe pavilion; SRM workplace (R49)) |

|

No use of approved string for the food contact and failure to store this string in a clean and dry place (R46) |

|

Partial respect of the abattoir hygiene rules by the drivers during the transport of meat (R47) |

|

Absence of training sessions for the personnel (R30 ; R45) |

|

No alternate use of several knives for the bleeding (R46) |

|

Absence of orientation of carcasses which underwent an accident of evisceration (R46) |

|

Slight proscription of the contacts by frictions of the carcasses or quarters with the abattoir floor, walls , wall of trucks (during the shipping ) (R47) |

|

Absence of canteen attendance regulation (R19) |

|

No proscription of notches in the muscle (the tools should not be planted in the meat) (R46) |

|

Absence of storage and cleaning facilities of the working clothes (R18) |

|

Absence of rectum bagging (R46) |

|

Absence of toilets and dressing rooms (R17) |

|

Absence of esophagus closure by ligature (R46) |

|

Absence of functional wash-hand basins and bin correctly laid out (R17) |

|

No application of the SRM withdrawal procedures (cleaning and disinfection of the materials and equipment in contact with SRM) (R46) |

|

Non-existence of slaughterhouse visit circuit for external actors (R38) |

|

No application of the personnel cleanliness rules (R30 to R36) |

|

For the handling of classes C and D animals , no washing of hands between each carcass, at all the workstations where a contact with leather is possible (R46) |

|

No drafting and diffusion of the “Hygiene Gold Rules “ to the whole abattoir personnel (R29) |

|

No mastery of the control at the animal reception ( sorting of clean animals, papers controls ) (R58) |

|

A lack of a systematic check of the knives’ good state, at the appropriate time following the organization of work(R46) |

|

No respect of udder integrity during its ablation(R46) |

|

No hands washing at least between each carcass, at all the workstations, where a contact with the digestive contents is possible (R32) |

|

Circulation of wood in the production workshops (R25) |

|

Absence of knives holder in a stainless wire’s lattice; absence of identification engraving on knives blade; presence of anti-skid plastic on knife handle (R46) |

|

Absence of a cleaning and disinfection plan (R50 to R54) |

|

Partial realization of gall bladder ablation without piercing it (R46) |

|

Absence of alternated use of different knives in order to be able to clean and disinfect them in compliance with approved method (R46) |

|

Absence of staff’s medical monitoring; Partial prohibition of medicative sprays use in the production workshops (R28) |

|

Absence of hygienic ablation of stick wound (R46) |

|

Absence of a development plan for fighting against pests (R55) |

1R <-> is the abbreviation of the word “recommendation” and the number which follows the R represent represents the recommendation number as presented in the guide to good hygiene practice (GGHPAHPSCA).

Neural Discriminant Analysis

The discriminant analysis carried out using the data collected from the nature of the slaughterhouses show a relative drop in the costs during learning. The estimation of the gap between the classes observed and the classes calculated during the discrimination process varied among 0.5 to 0.1 *10-4 (Table 4), the new classes stemming from the discriminant analysis. Classes of 100% purity come up from this new classification.

DISCUSSION

Perception of Basic Hygiene Rules

Traditional slaughterhouses in Cameroon still depict the clear implication of traditional authorities in their management (Mravili et al., 2013). This situation impacts directly on the functioning of these structures, because the techniques used in the treatment and manipulation of the carcasses are still archaic. This is why, the understanding of the perception type of basic hygiene rules demonstrated by the assistant butchers, passes through the search of personal information concerning them. As such, the MFCA revealed an opposition between the modality of cleaning work utensils with tap water and detergent, to that represented by the absence of cleaning of work utensils. Comparing the GGHPAHPSCA cleaning process to the methods of the traditional slaughterhouses, reveals a fairly good perception of cleaning by these assistant butchers. The confrontation of modalities at the level of axis 1 will portray the antagonism between a fairly good and a bad perception of elementary hygiene rules.

The HAC (Figure 1) and the NDA (Table 2) confirmed by class 3/3, show the existence of a category of assistant butchers with a primary school education, who had a fairly good perception of basic hygiene rules. Despite the adhesion of 67% of assistant butchers to this class, the result remains low as compared to modern slaughterhouses. As a matter of fact, Nel et al. (2004) showed an adhesion of 92% of assistant butchers to the regular cleansing of hands. These results could be explained by the belonging of employees of these traditional structures in urban centres (Ngaoundere, Garoua, Maroua) in Northern Cameroon that inhabit quite a large number of educated people (NIS, 2010). The training given to these assistant butchers in primary school ties with the KAP (Knowledge, attitude, practice) model (Rennie, 1995), which stipulates that the behaviour or the practice of an activity depends on the knowledge of an individual and that the acquisition of new information will lead directly to the acquisition of new information which will get directly to a change of attitude, consequently, to the individual behaviour.

Adeyemo et al. (2009) underlined the problem faced concerning the supply of water in traditional slaughterhouses. Alongside this problem, could be mentioned the lack of means, which is generally the reason why river or well water is used without detergent for the washing of work clothes in these traditional slaughterhouses. This aspect has been fully taken into account in our study. In effect, axis 2, opposes the relative perception to the usage of river/well water in the washing of work clothes, to the cleaning of work clothes following the stipulated norms. Compared to the pre-cleaning phase described in the GGHPAHPSCA, the perception of the usage of unclean water has at least the advantage through mechanical action to reduce the amount of filth on work clothes. This is why this perception has been considered as average in the conception of basic hygiene rules. Axis 2 confirms the contrast between the two average visions of basic hygiene rules. One of the visions suited those young assistant butchers (aged less than 30 years) localized in the north and far north regions of Cameroon, while the other vision was held by those individuals belonging mainly to slaughterhouses in the Adamaoua re-gion. This remark was confirmed by the HAC and the neural discriminant analysis which identifies class 2/3 as the one that associates assistant butchers to the average perception of basic hygiene rules. The age difference observed between the assistant butchers of the north and far north regions as compared to those of the Adamaoua region could be due to the fact that meat professionals in the latter are made up mainly of the Hausa ethnic group (Mbaku, 2005), whereas those of the formers are made up of a mixture of different ethnic groups (Beauvilain, 1985). Even though 80% of assistant butchers interviewed were less than 40 years of age, the average perception of basic hygiene rules was found in the two age groups. This implies a certain stability in the transmission of the perception of hygiene rules between generations.

Table 4: Percentage of accurately classified slaughterhouses.

|

Output classes |

Ghp application |

highlyranked |

Badlyranked |

Total |

% of highlyranked |

Purety of ranking |

|

Class 1/3 |

Average application of GHP |

6 |

0 |

6 |

100 |

100 |

|

Class 2/3 |

Bad application of GHP |

8 |

0 |

8 |

100 |

100 |

|

Class 3/3 |

Fairly good application of GHP |

1 |

0 |

1 |

100 |

100 |

|

Total |

15 |

0 |

15 |

100 |

100 |

The average perception of basic hygiene rules presented at the level of axis 1 will also be developed at the level of axis 3, where it is faced with a poor conception of basic hygiene rules. The confirmation of class 1/3 with regards to the poor knowledge of essential hygiene rules was done through the HAC and the neural discriminant analysis. The association of illiteracy to the poor conception of hygiene rules could be explained using arguments contrary to those listed in class 3/3. In a nutshell, assistant butchers who adhere to class 1/3 only represented just 6% of the population under study. This falls in the same line with the one (7.7%) found by Haileselassie et al. (2013) in Ethiopia. This result shows that if an opportunity is opened to train assistant butchers (67% of literates), this could substantially lead to an improvement upon the quality of meat that comes from the traditional slaughterhouses of Northern Cameroon.

Characterisation of Beef Production System

The varieties of traditional slaughterhouses have already been described in developing countries (Trent et al., 2003). The present study considers this diversity in order to determine according to the GGHPAHPSCA, the differentiation parameters of these slaughterhouses. The description of sanitary practices studied at the level of axis 1 reveals a strong contrast between the modalities, which globally demonstrated the non-respect of Good Hygiene Practice (GHP) as compared to those with a fairly good application of GHP. As modalities that illustrate the respect of hygiene rules we could name: a thorough cleaning of brushes/squeegees; a storage of by-products shielded from the pests; a thorough cleaning of saws; a partial limitation of beef barn contamination; a prohibition in the contamination of meat and by- products etc. This shows that the best application of hygiene principles is due to a fairly good organization and division of labour during the treatment process of carcasses. This hypothesis was confirmed by the HAC and NDA which will define class 3/3 illustrated by the production system of the Garoua municipal slaughterhouse. Actually, the Garoua municipal slaughterhouse had a minimum investment in buildings, such as overhead rails, a partial conformity in their lay out plan and an average circulation of atmospheric current. This category of slaughterhouses could be classified as being an intermediary system between the modern and traditional system of beef production in most developing countries.

The analysis of the putting into practice of GHP by axis 2, confirms the antagonism between an average usages, as opposed to the non-respect of GHP. The confrontation of a modality such as the non-compliance of surfaces (a slab with many holes), to the absence of space (no slab), illustrates the opposition between the average and the non-respect of GHP. The cluster analysis distinguishes class 1/3 after the aggregation of slaughterhouses of a given dimension (assistant butchers > 21; number of slaughters per day >10). This situation could have led to the application of similar hygiene practices in most of the big slaughterhouses. Nevertheless, the slaughterhouses of Yagoua, Guider and Dang, despite their small sizes are joined to the slaughterhouses with large sizes. This implies that the use of GHP in traditional slaughterhouses does not depend on the size of the slaughterhouse, but, on the determination of the personnel of these structures to the application of hygiene rules (Nwanta et al., 2008).

The neural discriminant analysis confirmed the existence of class 1/3 whose slaughterhouses were specific by their partial compliance in the cleaning of surfaces and production material. As such, the shift in an average use of GHP in a traditional production system of beef passes through the development of cleaning and disinfection protocols (Mravili et al., 2013).

Whatever the axes chosen, the modalities relating to the poor application of GHP have been presented. The grouping (figure 2) of slaughterhouses of small dimension (assistant butchers ≤ 21; number of slaughters per day ≤ 10) was equally observed presenting a homogeneity in the hygiene practices used at the level of medium size slaughterhouses. That notwithstanding, the Kousseri slaughterhouse with 36 assistant butchers and 15 cattle slaughtered per day, was an exception. That is why the use of GHP could not be in relation to the narrowness of the said structure, but for the reasons listed in class 1/3 (see previous paragraph). The neural discriminant analysis reaffirmed the existence of class 2/3 which was different from the other classes by the modalities concerning the absence of cleaning and disinfection; to the non-compliance of the surfaces of the building and of the separation of pure areas from the polluted ones. These results show that the fundamental difference of the other classes of slaughterhouses with class 2/3 is mainly characterized by the parameters which could be corrected through the organization of work and the putting up of minimum investments on the surfaces of the building.

In a global perspective, the common characteristics to all the traditional slaughterhouses studied (table 3), is that, they all presented weaknesses in the management of the workers and work procedures. These general parameters were equally identified by many other research works on traditional slaughterhouses in Africa (Haileselassie et al., 2013; Ndalama et al., 2012; Komba et al., 2012; Seeiso and McCrindle, 2009). However, the additional contribution of these characteristics lies on the inventory of all the weaknesses common to traditional slaughterhouses in relation to GGHPAHPSCA. Associating the similarities to the specificities of classes 1/3 and 2/3 could be explained by the fact that in the traditional sector of beef production, the main actors are: the personnel (work force), the production process, and the animal (representing the meat to be produced).

The study of hygiene practices observed did not expose the effect of the perception of basic hygiene rules, whatever the class and the type of production concerned. This remark could be demonstrated through the important number of variables considered for the analysis. That is, 64 active nominal variables associated to 155 modalities, and 29 illustrative nominal variables associated to 85 modalities. Therefore, the calculation of learning cost in the neural discriminant analysis was calculated up to the margin of 0.00001. To improve on the consideration of this perception, it would be necessary to increase the number of slaughterhouses to be analysed.

CONCLUSION

In conclusion, this research showed the important role that a minimum level of education could play in ameliorating the perception of basic hygiene rules by assistant butchers in traditional slaughterhouses in Cameroon. The analysis of the GHP application presented in the GGHPAHPSCA confirms that the amelioration in the use of GHP in traditional slaughterhouses passes imperatively through the improvement in the hygiene practices used in relation to the management of the personnel and the production process of traditional slaughterhouses. These conclusions should however be confirmed by a study on the impact of these hygiene practices on the microbiologic contamination of meat produced.

ACKNOWLEDGEMENT

We would like to be grateful to the MINEPIA (Ministry of Livestock, Fisheries and Animal Industries) staff of Northern Cameroon, for their collaboration during this study. Our gratitude also goes to Dr Stanley Fon Tebug for proof reading of the manuscript.

Conflict of interest

We assert that this study has no conflict of interest.

REFERENCES